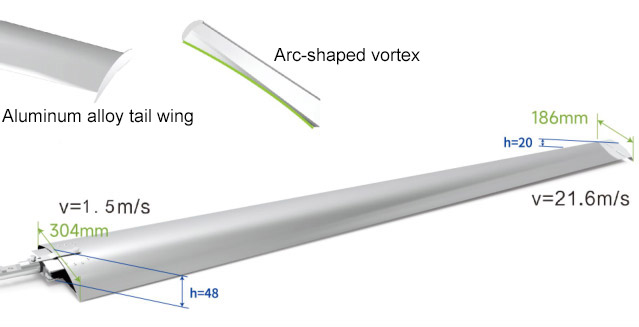

Through aerodynamic simulation analysis, applying equal chord length theory, combined with the principle of relative linear velocity, a streamline variable cross-section fan blade was developed and designed, which gradually narrowed and thinned from blade root to tip, with more balanced force, more uniform air supply, and no cavity in the center.

Adopting 5052H32 high grade 1.5mm aviation grade aluminum alloy motherboard, precision CNC forming, higher strength and flexibility, ensuring no fracture. Lighter and safer in weight. Each blade only weighs 6.7 kilograms (7.3 meters in diameter, excluding buffer parts), with a small number of blades and light weight, reducing motor load, extending service life, and ensuring safety and energy conservation.

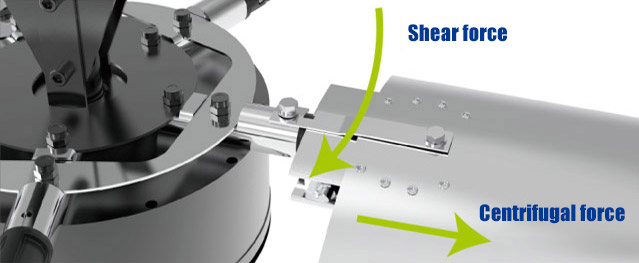

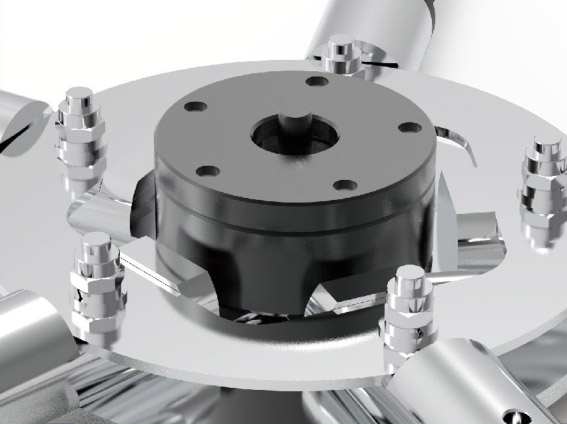

16 high-strength steel core rivets are separated and riveted up and down (a single rivet can withstand 1500kg tension), forming independent surfaces on the upper and lower layers of the blades to withstand the strong centrifugal force when the fan is running at full speed.

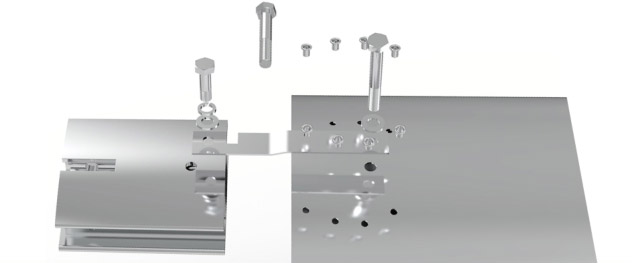

With high-precision coordination with the blade buffer chamber, it efficiently absorbs stress and airflow vibration from the blade, reduces motor load, and extends service life.

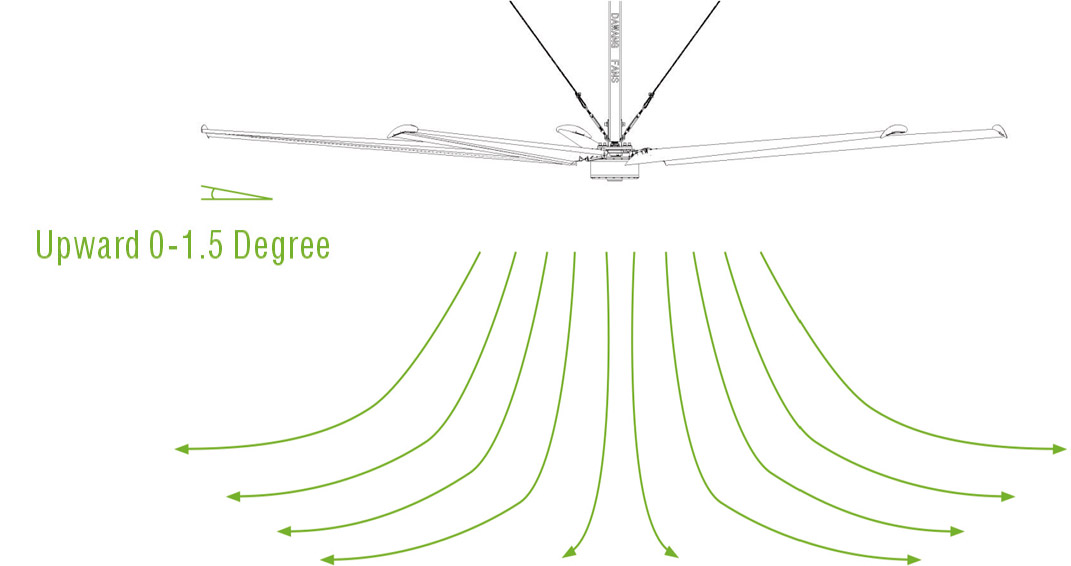

There is a precise angle limit in the buffer chamber, and the blade handle is connected to the buffer chamber to form a 1 ° micro upward movement, effectively eliminating the reverse force generated during the fan operation and forming a conical airflow, achieving no voids in the center and increasing coverage.

By interlocking the upper and lower pressure plates with the concave and convex steps of the blade handle, the blade handle is integrated with the hub/motor, and the overall structure is used to withstand the centrifugal force during fan operation, without any stress on all fasteners.

A patent inner cone kit is installed in the center of the hub, forming a structural self-locking with the output of the inner rotor motor, which naturally expands and tightens under the action of gravity, ensuring reliable connection between the overall hub and the motor.

Anti fall ring and inner rotor motor: connect 5 blade handles with the anti fall ring through bolts, and form a sleeve hanging with the chassis of the frame to prevent falling due to wheel hub detachment or shaft breakage;

The anti fall ring forms a collar with the motor flange, ensuring effective hooking in the event of motor shaft breakage and ensuring safe operation.

Large span, high height, heat stroke, low attendance rate, low work efficiency, and high turnover rate caused by high temperature and stuffiness, exhaust dust, moisture and mold, and temperature stratification among employees.

The space is relatively enclosed, and the indoor air is turbid. In summer, it is stuffy, and in the rainy season, it can cause heatstroke, slippery floors, high bacterial concentration, and high energy consumption of central air conditioning. It cannot solve problems such as air turbidity and temperature stratification.

Frequent movement of staff, indoor stuffiness, insufficient ventilation, heatstroke caused by high temperature and humidity, and deterioration of goods.

Semi open architecture, relatively dirty and messy. The environmental control of animal husbandry is related to the growth and development of livestock, the production of milk for disease and epidemic prevention, and the production of qualified milk.